Certified valves with TÜV / PED and/or CE Type Test Approval

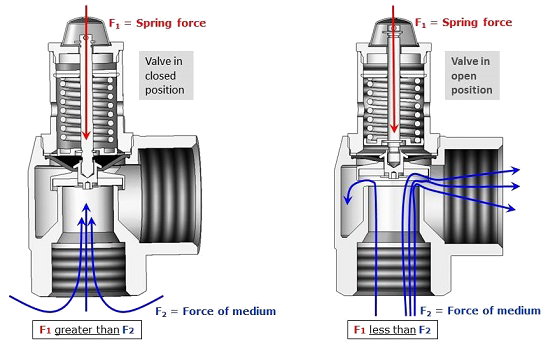

Normal lift- Full lift opening / closing characteristic

Higher blow-off capacities than pressure relief valves

Valve without certification / approval ( without safety function according to PED )

Proportional opening- / closing characteristic

Lower blow-off capacities than safety valves